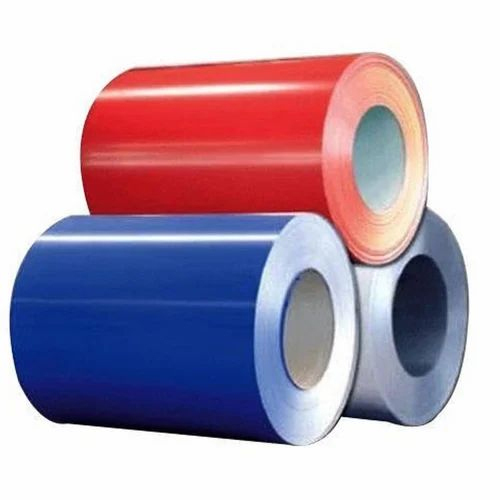

Aluminium Color Coated coil

Price 200 INR/ Kilograms

Aluminium Color Coated coil Specification

- Usage & Applications

- Industrial

- Material

- Aluminium

- Product Type

- Aluminium

- Shape

- Round

- Hardness

- Rigid

- Surface Treatment

- Coated

- Color

- Multi

- Warranty

- Yes

Aluminium Color Coated coil Trade Information

- Minimum Order Quantity

- 300 Kilograms

- Supply Ability

- 300 Kilograms Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About Aluminium Color Coated coil

With the intense apprehension, we are supplying and trading exemplary assortment of Aluminium Color Coated Coil / Aluminum Coils in delhi. Owing to the features like durability and high tensile strength these coil tapes are extensively used for various applications like distilleries and heat exchangers. In addition to this, our valued customers can procure these Aluminium Color Coated Coil with the customization in accordance with their specific need. Moreover, we offer the wide range of coil tapes to our esteemed clients at very nominal rates.

Key Features of Aluminium Color Coated Coil:

- Better protecting characteristics

- Responds with the oxygen

- May create thin oxide layer

- Layer is thick

Product Details of Aluminium Color Coated Coil:

|

Surface Treatment |

Color Coated |

|

Material |

Aluminium |

FAQ of of Aluminium Color Coated Coil:

What is an aluminum variety covered curl?

An aluminum variety covered loop is a sort of aluminum curl that has been painted with a layer of variety covering material to give it an alluring and strong completion. The covering material is typically a sort of pitch or polymer that is applied to the outer layer of the aluminum utilizing a cycle known as loop covering.

What are the benefits of utilizing aluminum variety covered loop?

The upsides of utilizing aluminum variety covered loop incorporate its appealing completion, erosion obstruction, sturdiness, and flexibility. The covering material can be modified to suit explicit tasteful prerequisites, and the aluminum substrate gives magnificent protection from consumption, making it ideal for use in a great many applications.

What are the uses of aluminum variety covered loop?

Aluminum variety covered loop is generally utilized in the development business for material, cladding, and exteriors, as well as in the car business for trim and body parts. It is additionally utilized in the production of domestic devices, like fridges, clothes washers, and cooling units.

What are the various sorts of covering materials utilized for aluminum variety covered curl?

The covering material utilized for aluminum variety covered loop can be separated into two classifications: polyester and PVDF. Polyester coatings are commonly utilized for inside applications and give a smooth, shiny completion. PVDF coatings are more strong and impervious to blurring and chalking, making them ideal for outside applications.

What are the variables to consider while choosing an aluminum variety covered curl?

The variables to consider while choosing an aluminum variety covered loop incorporate the kind of covering material, the thickness of the covering, the substrate material, and the variety and finish of the covering. Different elements to consider incorporate the application, the degree of UV openness, and the ecological circumstances.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Color Coated Coil Category

Aluminium Color Coated Coil

Price 200 INR / Kilograms

Minimum Order Quantity : 10 Rolls

Color : Blue, Red

Hardness : Rigid

Material : Aluminium

Usage & Applications : Industrial

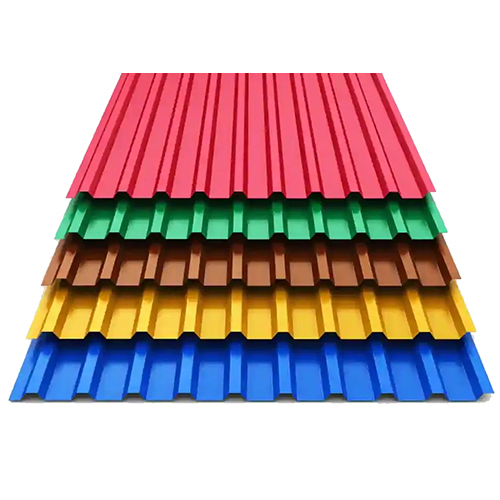

Aluminium Color Coated Sheet

Price 200 INR / Kilograms

Minimum Order Quantity : 300 Kilograms

Color : Multi

Hardness : Rigid

Material : Aluminium

Usage & Applications : Industrial

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese